Consulting Services

E&G Associates has considerable consulting experience in support of granulation and compaction processes, as well as surrounding material handling issues, relying heavily on powder characterization of relevant formulation properties.

Representative Assignments

Our approach has led to lasting solutions for a variety of customers. Representative examples of our contributions & capabilities include:

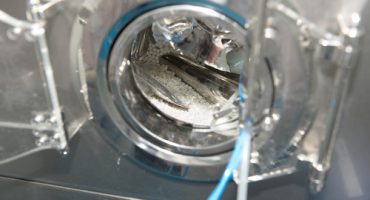

Design and commercialization of a state-of-the-art powder shear cell to assess powder friction and cohesion properties. Incorporated into development work of several clients, including in-process manufacturing release specifications for filling operations of one client and a joint CRDA with the FDA of another. Similar instruments are under design for compaction, IGC, caking, segregation and granulation studies.

Scale-Up and Powder Characterization Methodologies

Development of scale-up and powder characterization methodologies for the design and control of granulation systems based upon physicochemical properties of formulations.

Material Handling

Material handling applications at the manufacturing scale, ranging from hopper and feeder design to eliminate arching or ratholing to elimination of segregation of blends.

Solid Dosage Handling

Material handling applications at the solid dosage form scale. Applications include powder applicator redesign, development of flow specifications for dosators of inhalation products, and identification of critical properties to prevent encapsulation failures.

Dry Powder Coating Applications

Elimination of defects in a variety of dry powder coating applications, ranging from high-voltage electrostatics applications to granule coating to high temperature sintering of coatings.

Characterization Tools

Development of a variety of characterization tools to assess surface hardness and bulk particle/crystal/granule strength, as well as other mechanical properties, as they relate to powder flowability, caking, crystallinity, tabletting, and attrition resistance.

Powder Flowability and Particle Properties

Determining the relationship between bulk powder flowability and particle properties, including surface chemistry, hardness, and particle size distribution.

Dust Propensity Evaluation

Dust propensity evaluation, utilizing both filter loading and photometric response, coupled with in-line particle size measurements. Has led to re-classification by regulatory bodies of some compounds in terms of restrictions and handling.

Emulsion

Elimination of settling and development of quality control specifications to extend shelf life of emulsion products.

Caking

Proprietary approach to the study and resolution of caking problems involving caking dilatometry and shear testing.

Flow Aids

Selection of most appropriate flow aids, based on interfacial compatibility.

Education

Conduct regular external and in-house continuing education courses in powder flow, material handling, powder characterization and granulation/compaction.

Litigation

Patent review and technical litigation, ranging from consumer products to pharmaceuticals, in all areas of powder processing and manufacturing.

Contact us with regard to your specific needs or testing requirements

Contact Us